5 September 2018

Not Pulp Fiction: A New Pressure on the Paper and Forest Product Industry

Many people believe that the paper and forest product industry is in decline, especially considering the digitalized world that we live in. While the global market for graphic paper, used predominantly for newspapers and writing paper, has seen a decline since 2015, the paper and forest product industry as a whole has been growing.

The demand for packaging is growing annually due to a flourishing online retail market, so too is the demand for more hygiene products such as tissues and wipes. Add to this the many new applications that are currently under development to substitute other materials such as plastics and light steel for example – materials which are often not as sustainable and environmentally friendly as cellulose fiber based pulp material. Finally, also contributing to this growing demand for virgin pulp, China imposed in July 2017, driven mainly by environmental concerns, an import ban on 24 types of waste materials for recycling that they previously accepted from foreign regions. Much of the waste paper was used in the production of cardboard boxes for online retailers such as Amazon. While it is too early to determine the final outcome or long term development of this decision, what is clear is that the competition and price for virgin pulp has increased dramatically since this ban was imposed.

Specifically focusing on softwood fiber that has been used for many years by Weidmann, and the electrical insulation industry in general, to produce our electrical grade Transformerboard and paper products, the medium term outlook shows continued strong growth in demand for such pulp. This situation is mainly driven by a global desire for stronger lightweight packaging and increased use of sustainable materials. When Weidmann buys pulp today, we are now competing in an evolving market with growing high demand and no planned increases to capacity. Couple that with the relatively small number of pulp suppliers who are able to produce electrical grade cellulose, and the end result is the record high prices that we are now facing.

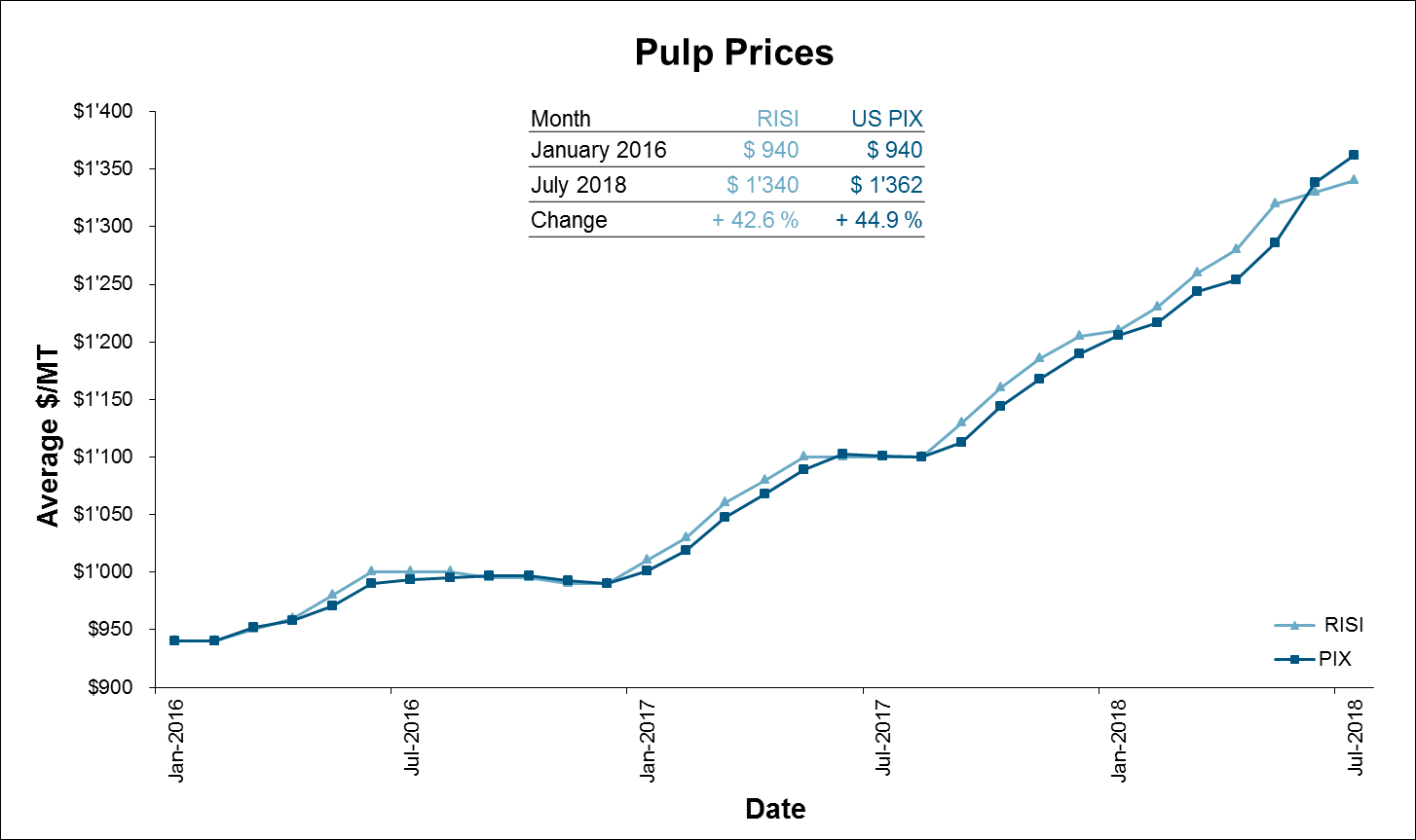

The impact of increasing prices for pulp as shown in the table below has a knock on effect across many industries. Cardboard box manufacturers for example have stated that since August 2017, the price of boxes has almost doubled, with the price for finished paper also doubling per ton.

Weidmann, along with others in our industry, continue to see not only significant price increases, but in some cases also supply restrictions for our key raw material. As the industry leader with a long history in the market, we are using all of our experience to effectively manage our suppliers of pulp and to find ways to further optimize our pulp needs – all with the goal to ensure that there is minimal impact to our customers. At the same time, we are also ensuring that we do not accept any lower grade materials that can have a direct negative impact on the high quality material we provide today, as many offers of lower grade materials are now finding their way into the industry supply chain.

When in future you are using cardboard packaged goods, take a moment to consider, that the packaging was manufactured with the pulp that got away from our markets, and when you discard of that item, remember that is the unlucky material that could have spent decades providing reliable service in a high quality transformer.