Stay Informed: Project Air 2021

11th March 2022: Please note that due to the current conflict in Ukraine, data relating to the status of projects AIR 1-2-3 is currently not up-to-date. Please contact your account manager for further information relating to open and future orders.

Weidmann Electrical Technology has been in the business of electrical insulation for more than 140 years. For a company to successfully exist for this length of time requires determination, a strong focus on quality, and of course the ability to continually improve and adapt to market conditions in order to remain competitive.

The globalization of our industry drives the need for our customers to not only deliver high quality products, but also deliver at a highly competitive price and terms. In order to ensure that we as a key industry supplier can remain competitive, and deliver the same high quality products as you have come to expect from Weidmann, we are currently investing in the relocation of a number of our Swiss production lines.

Relocating certain production lines from Switzerland to other plants not only provides us with the opportunity to increase our competitiveness through modernizing our equipment and approach, it also presents us with an opportunity to improve and increase our capabilities to serve you better in the future.

The investment we make today in new production lines will enable us to meet the future demand of our customers, at a competitive price, and with new processes, improved supply and quality.

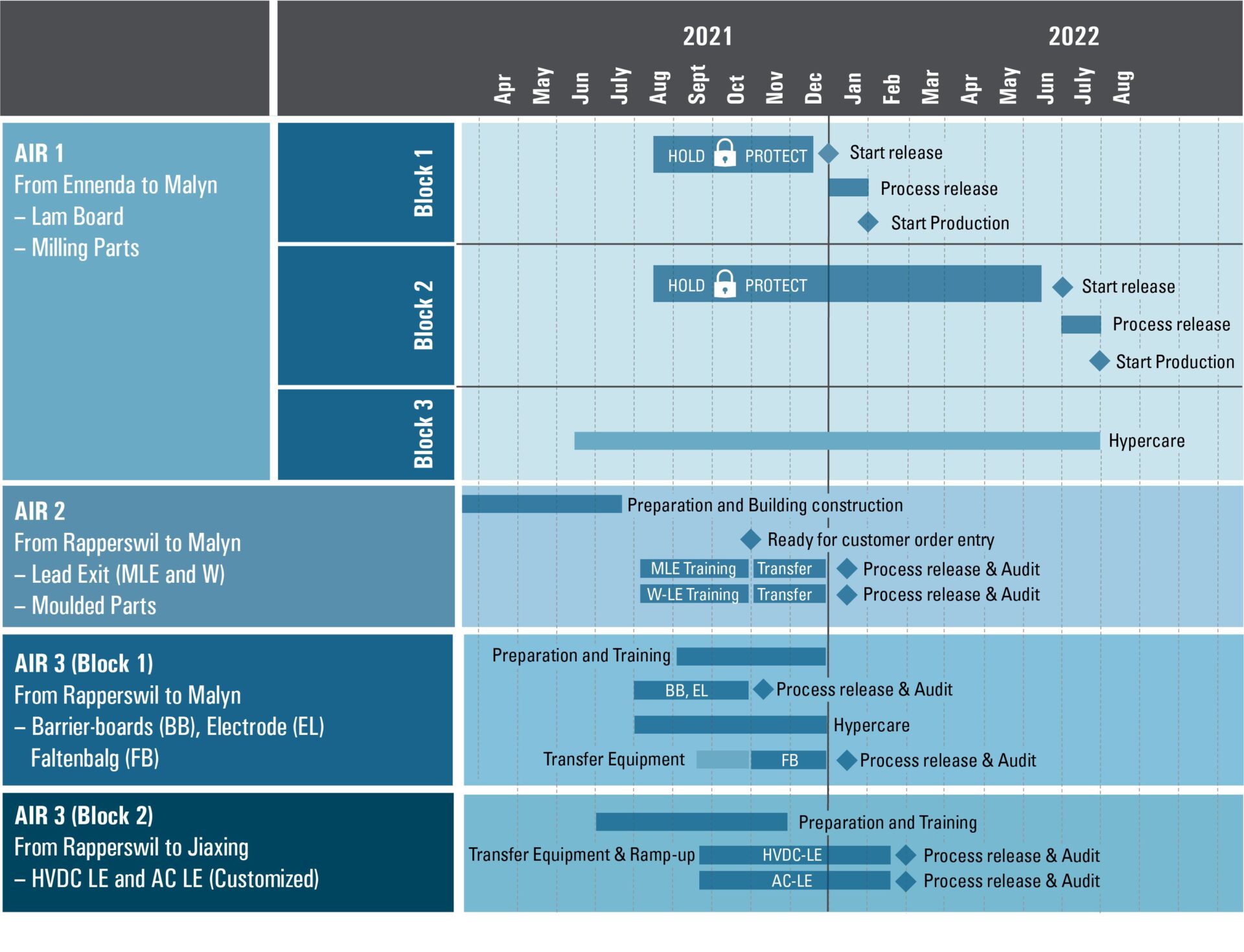

Project Status: Hold & Protect / Progressing

Active Projects: 3/3

Completed Projects: 1/3

Last Updated: February 16, 2022

Summary of current project status:

What does Hold & Protect mean?

As we progress through the project, at critical milestones we assess the risk of the next key actions and the potential they have to impact customers and supply. If we deem the risk that customers will be affected is high, we reserve the right at these times to initiate Hold & Protect to pause certain elements of the project.

Air 1 (block one):

– Pre-production material: The build up of stock in Ennenda continues (see Air 1, Block 2)

– Dismantling 1st Press: Complete.

– Transfer equipment (1st press): Complete

– Assembly of 1st Pagnoni press in Malyn facility: Complete.

– The press is currently undergoing test and verification as part of our internal equipment and process release: In progress*

* Please note that due to issues with the Automatic Press Protocols, we are currently experiencing a 2-week delay in the test and verification stage. The Automatic Press Protocol issue was identified in initial test production runs, the protocols are currently being amended/corrected to ensure stable, reliable adherence to the Weidmann internal quality standard for the material produced. Please note that this delay does not impact any current customer orders.

Air 1 (block two):

– Preparation for the dismantling of Press 2 remains in Hold & Protect stage. Due to high customer loading in 2022, the second Pagnoni press will continue to operate in Ennenda, Switzerland. A further review of the Hold & Protect status will be conducted in Q2 2022.

– Production of stock material continues in Ennenda, Switzerland (Bell press material).

Air 1 (block three):

– Hypercare: Throughout the Air project blocks 1 & 2, Press 3 will remain operational in Ennenda, Switzerland until the successful commissioning of Press 1 & 2 in Malyn to ensure uninterrupted production. The Hypercare phase will continue until further notice due to the Hold & Protect status of block 2.

Air 2 Completed:

– Preparation & Construction: The renovation of existing facilities is completed.

– Training (MLE and W-LE): Completed

– Rapperswil, Switzerland employees are now deployed to Malyn to support the initial production runs and finalize any remaining training requirements: Completed

Commercial orders are now being processed in Malyn, Ukraine.

Air 3 (block one) Completed:

– Barrier-Board and Electrode transfer is completed.

– First production units have successfully passed internal testing in Rapperswil, Switzerland and shipped/received by customers.

Air 3 (block two):

– On schedule, preparation and training are currently ongoing.

If you have a specific question or require support relating to this project, please click here or alternatively contact your account manager.