8. April 2021

InsuLogix® HMA - Maintain or React?

Introducing the InsuLogix® HMA: The ONLY online DGA monitor you will ever need.

What do you want to achieve with your online monitoring strategy?

There are many options when it comes to online Dissolved Gas Analyzers (DGA) for use in Power and Large Distribution transformers. Gas Chromatography (GC) systems, Infra-Red Spectroscopy (IRS), and also, entry-level low-cost devices that use proprietary technology.

Never before have we seen precision laser technology used in online DGA transformer monitoring systems – what are the advantages?

– Enables industry-leading accurate detection of very low amounts of gas (low detection limit of 0.5 PPM).

– Does not require ongoing maintenance and calibration once deployed in the field.

– Provides a cost-effective solution for critical gas monitoring, and significantly reduced total lifecycle cost of the monitoring system.

But before choosing a particular device, you must consider what your objectives are with online DGA monitoring and from these set your priorities.

Maintain or React!?

The Weidmann InsuLogix HMA measures Hydrogen, Moisture & Acetylene using the world’s first laser detection system that enables accurate measurement of gas with a low detection limit of 0.5 PPM. But why do we ask ‘maintain or react’?

Hydrogen (H²)

Detecting and reporting increased levels of Hydrogen (H²) gas in transformer oil enables transformer operators to ‘maintain’ the transformer asset with an appropriate response. It may be appropriate to increase oil sampling frequency to run comprehensive laboratory DGA analysis on the transformer oil, which enables effective decision-making on future maintenance requirements.

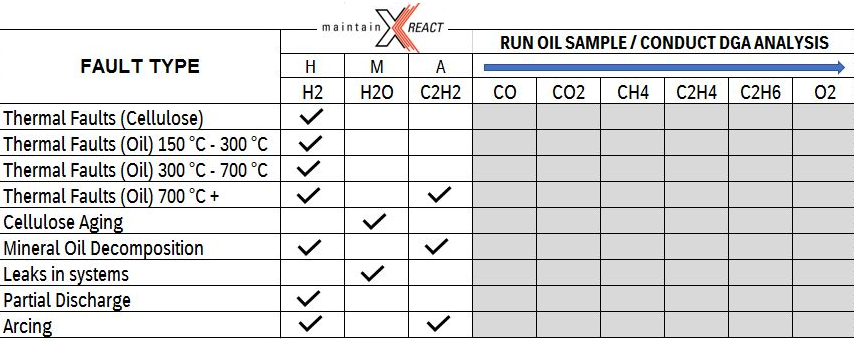

Using H² as an effective method of determining transformer condition is of course nothing new. Leading institutions and organizations around the world have already pointed out that H² is the perfect partner for making transformer maintenance decisions as it is triggered and increases under the majority of fault conditions (see table 1 below).

Moisture

If you are concerned about capturing cellulose aging of the insulation material, moisture detection within the transformer oil will provide a good guide. At Weidmann we know ‘a thing or two’ about cellulose degradation and while it is imperative that the aging of insulation materials is tracked, typically the breakdown happens at a slow rate and moisture detection, complemented with laboratory-based oil testing will enable you to maintain and prepare for any increased ‘loss of life’.

Acetylene (C²H²)

So when should you react? When do you really need ‘the alarm!’? Acetylene is well known to transformer operators as the critical gas. Even when Acetylene appears in small amounts, it is imperative to react and determine how critical the situation is and prevent the potential for catastrophic failure.

The InsuLogix HMA follows the three A principle:

Acceptable ‘total lifecycle cost’, providing a highly robust device, with minimum maintenance requirement and clear cost/investment justification to deploy across a complete fleet of transformer assets. Additionally, the device can be installed on a single transformer valve with no additional mechanical requirements.

Actionable data that adds value to the asset maintenance and operating procedure, along with critical performance data that can prevent a catastrophic failure.

Alarm data that accurately predicts the potential for failure or significant damage/loss of life of the asset, but minimizes false or unwanted alarms.

Table 1: Fault types